Thank you for your interest in hiring Cyber City Circuits for your PCB assembly needs. We offer an assortment of services, including...

- PCBA

- DFM Consulting

- Prototyping

- Circuit Board Design

- Firmware

- QC Testing

- Packaging

We need the following to process your quote. Send RFQs to Sales@CyberCityCircuits.com.

- Our completed quote form. <(-Link (Updated: 31-Dec-2025)

- Your gerber package.

- Pictures or renders of your board. Front and back.

- A high-level explanation of firmware or QC procedures to be ran.

- Any notes, questions, comments that you may have can be included in the email.

Important things to know:

- We require 10% overage on PCBs.

- We require 10% overage on all parts and 20% overage on all parts 0402 and smaller.

- Clients can earn bonus points by clearly marking the BOM line number on each kitted part they send. To make it even easier, we recommend marking the parts with the format "Job Number + BOM Line Number". Additionally, if you are ordering new parts for this order, you can use the same number as your customer number. Thank you.

- If we perform your assembly, we will need a position file. Here is how to do it in KiCAD.

- By submitting a Request for Quote you are agreeing to our Terms of Service.

- Find the complete and latest Terms of Service at https://cybercitycircuits.com/tos/

Please ship parts and other materials to:

Cyber City Circuits

Attn: D. Ray

336 Georgia Ave

Suite 106 Box 233

N Augusta, SC 29841

Assembly Tiers

Prototyping

- Low Quantities - No Minimums

- Part-sourcing services are available.

- No firmware or QC services.

- Stencil may be flex or framed.

- 3-Day, 5-Day, and 10-Day turnaround options available.

Small Business

- Quantities up to 500 PCB Assemblies.

- Part-sourcing services are available.

- Panelization Requirements

- Firmware and QC Services available.

- Framed stencil required.

Enterprise

- Quantities greater than 500 PCB Assemblies

- Part-sourcing services are available.

- Panelization Requirements

- Firmware and QC Services available.

- Framed stencil required.

- Blanket Ordering / Scheduled Ordering available.

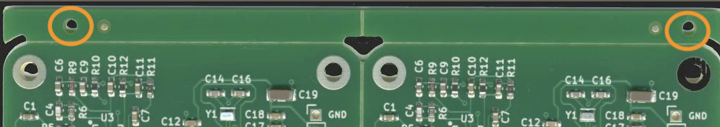

Panelization Requirements

During the manufacturing process PCB Assemblers will use edge rails through out the process to feed the boards through the various machines. Our machines work best when we can use mounting pins to hold your boards in place. Vendors like JLCPCB and PCBWay will panelize your boards with edge rails for you. If you don't want to or your design can't be panelized, there are other ways we can assemble your board and we can still help.

For more information, check out Much Ado About Panelization and Mounting Holes.

| Edge Rail Width: | Minimum 5 mm |

| Mounting Hole Sizes: | 1.05, 1.55, 2.05, 2.55, 3.05 mm |

Frequently Asked Questions

Q: Where do I ship parts?

A: Please ship parts to the following address:

Cyber City Circuits

Attn: D. Ray

336 Georgia Ave

Suite 106 Box 233

N Augusta, SC 29841

Q: Do you offer parts sourcing at all?

A: We source parts on a case-by-case basis. If you need help mitigating paneling issues, we're glad to source PCBs and stencils. If you have questions or need help, please ask. We don't mind helping.

Q: What type of stencil do you accept?

A: For very short prototyping runs, we can use a flex or framed stencil, but for all production quantities we require a framed stencil. We can help you with any questions about sizing or material.

There are many places to source a framed stencil. We recommend OshStencil, JLCPCB, and PCBWAY for your stencil needs.

Q: Who do you recommend for PCB Fabrication?

A: There are many different places you can shop from to have PCBs fabricated. Most assembly shops do not manage PCB fabrication. Its two different processes.

If shopping for US-made PCBs, we highly recommend Sunstone Circuits. We have used them a bit and have been happy with their services in the past.

If shopping for cheaper PCBs, vendors like JLCPCB, PCBBUY, and PCBWAY all make a quality product at affordable prices.

Q: What can I do to make my assembly process as easy as possible?

A: There are a few things that you can do that can save a lot of time, money, and stress throughout the process.

- When ordering your parts, use 'Job Number' + 'BOM Line Number' as your customer number.

- If you have already ordered the parts, writing the line number on the bag with a sharpie makes the check in process a lot quicker. This isn't required, but it is helpful and appreciated.

- Make sure you include enough overage parts for your assembly.

- Be confident with your design before you go into production.

- We offer prototyping services as well, if you want to make a handful of assemblies before going into production.

Q: How do I generate a Pick and Place file?

A: This is a good question. We wrote a blog article, explaining how to do this in KICAD, called KICAD Tip: Generate a Position File. If you have any further questions, please feel free to contact us.

Q: How can I get JLCPCB to do the panelization for me?

A: I'm glad you ask, this is a great way to manage all of these panelization requirements.

JLCPCB has a few requirements in order to panelize your board:

- it will need to have a non-irregular shape.

- the shorter side must be longer than 70mm.

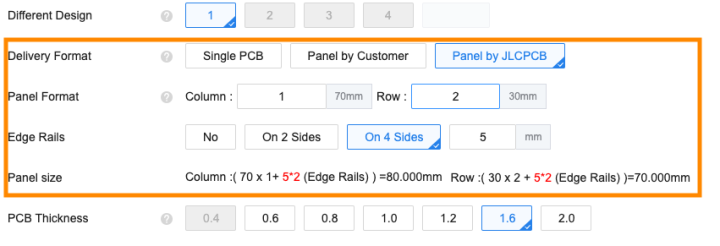

Let’s go through what the different options on JLCPCB’s quote form are for panelization.

- Delivery Mode – There are three options here. ‘Single PCB’ is the default option and the one you’re likely most familiar with. ‘Panel by Customer’ is an option for you to select if you have panelized the boards yourself, before submitting your gerbers for production. ‘Panel by JLCPCB’ is the option we’re interested in here.

- Panel Format – You can have your boards panelized 5 rows of 4 boards, 1 row of 3 boards, and so on. When considering how many boards to put on your panel, things like board thickness, the size of the individual boards, and if any components will overlap from one board to another during assembly. Generally we like to keep our panel sizes to less than 150mm x 150mm, but we can process boards larger than that. It seems to be the most economic size for panelization.

- Edge Rails – Here we have three main options. When panelizing, we have found that 5mm edge rails on all four sides are great for processing and assembly.

Q: I can't panelize my board, what can I do?

A: Good question. In that case, we could complete assembly with just mounting holes placed near the corners. For more information on this, please read our blog post Much Ado About Panelization and Mounting Holes.

Additional Notes can be found on JLCPCB's Website.